National Maritime Museum

A comprehensive upgrade and refurbishment to the Grade I listed building, improving its roof and glazing for improved sustainability visitor experience

-

Client

National Maritime Museum

-

Location

Ocean Court, Greenwich, London SE10

-

Architect

WDI (internal division)

-

Contractor

Willmott Dixon Interiors

-

Surveyor

G&T

-

Sector

Leisure

-

Products

About the museum

Greenwich has been home to a naval-based art gallery since the early 1800s, but the idea for the National Maritime Museum as we recognise it dates back to 1927, when a public appeal was launched by the Society for Nautical Research to develop a ‘national naval and nautical museum’.

Sir James Caird, a wealthy member of the Society, purchased the A.G.H. Macpherson Collection of over 11,000 maritime prints, along with ship models and many other items, to help begin the Museum’s collection. The Caird Archive and Library is named after Sir James in recognition of his contribution.

Ten years in the making, the National Maritime Museum was opened by King George VI on 27 April 1937, with the Museum’s name having been suggested by Rudyard Kipling.

Completed: 2025

You can view a video of our works here.

This project was also featured in a news article on Eckersley O’Callaghan’s website [Climate Friday ] Revitalising glass roofs in historic buildings, how do we approach restoration in a sustainable way?

Client brief

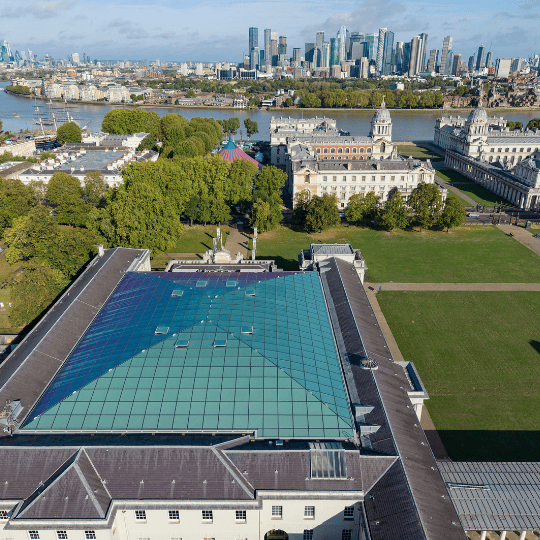

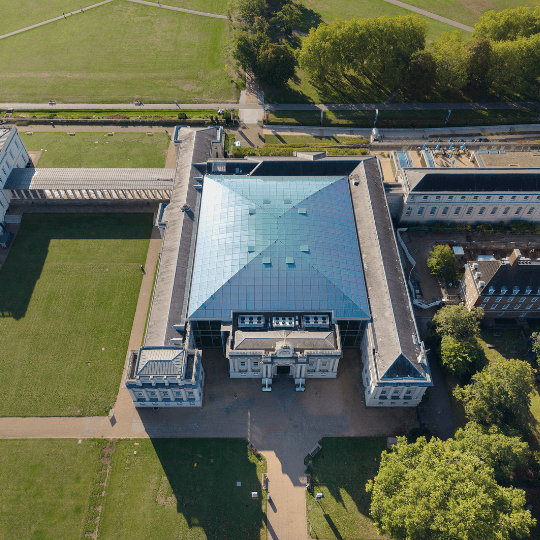

A comprehensive upgrade and refurbishment to the Grade I listed National Maritime Museum, improving its roof and glazing for improved sustainability visitor experience.

The project focuses on significant roof upgrades to the Grade I listed National Maritime Museum, a renowned cultural landmark in London. These improvements aim to enhance the visitor experience while addressing key structural and environmental concerns.

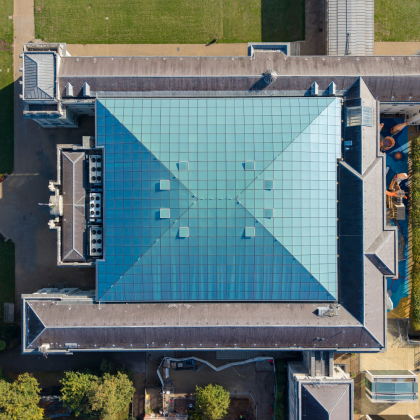

A central element of the refurbishment is the installation of over 2,500 m² of an enhanced Solar & Acoustic Performing Glazed Atrium Roof above the museum’s central court. This water ingress problem reduces solar heat gain and improve both energy efficiency and acoustic performance.

Our scope

We led the restoration of the National Maritime Museum in Greenwich, focusing on replacing 2,500 m² of roof glazing and clerestory windows. Our team designed, supplied, fabricated, and installed a new rooflight to resolve issues with watertightness, overheating, and enhance acoustic performance in the covered atrium.

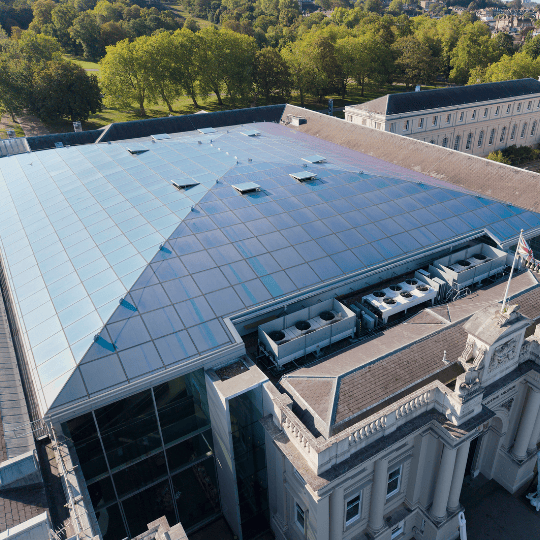

We used the Raico System for the Roof Glazing and the Schüco AWS70 System for the clerestory windows, integrating automatic opening vents and coordinating with the building management system. This project preserved and enhanced the Museum's historic building, ensuring visitors could continue experiencing its vast collection in an improved, energy-efficient space.

During the replacement of the Roof Glazing, the Central Court exhibits, including the Royal Barge with an estimated value of £30m, remained in place. To protect these exhibits, we provided an internal drained roof on top of the Birdcage Scaffolding.

Key challenges

Challenge 1

Completing the works through the winter months

Challenge 2

Providing the tower crane with a 75m reach across the museum roof

Challenge 3

Delivering the project whilst the museum remained open with the exhibits in place directly under our works

The result

The completed project has transformed the National Maritime Museum’s central court, significantly improving its environmental performance and visitor comfort.

The new sun-protected glazing has enhanced natural light while reducing overheating and water ingress, creating a more sustainable and acoustically improved space.

With our extensive experience in working with heritage buildings, the upgrades to the building’s systems have ensured long-term efficiency, preserving the museum’s historic integrity while improving the visitor experience.

Detailed product listing

- RAICO Plant on Glazing System

- RAICO Smoke Vents

- D+H UK Roof Vent & Vertical Actuators

- Schuco AWS 70HI Vertical & Include Window Systems

- Bespoke Sheet Metal

- Eurosafe Latchway System

What we did

#1

Safety Ranking

Achieved top position in Monthly Safety League on numerous occasions

4

Monthly Safety Awards

Our team members won Individual Monthly Safety Award on four occasions out of eight

0%

Incidents

Completed high-risk installation using rope-access without any incidents - no accidents or near-misses